Cottage cheese, once a niche dairy product, has seen a dramatic surge in popularity in recent years, largely driven by social media trends. Platforms such as TikTok have introduced a whole new generation to its benefits, especially its high-protein and low-fat qualities. What began as a simple ingredient for fitness enthusiasts has evolved into a mainstream product, with recipes showing how cottage cheese can be incorporated into smoothies, bowls, and even savory dishes.

As cottage cheese becomes a go-to choice for those looking for healthy, versatile food options, its consumption has soared, and it has become a staple on supermarket shelves. This rise in demand is not just a fleeting trend; it’s the result of a broader shift in consumer behavior toward health-conscious eating.

According to recent market research, it appears that cottage cheese production is likely to continue its growth in the coming years. This is especially exciting for cheese producers, as it represents an opportunity to tap into an increasingly health-conscious consumer base. The shift toward protein-rich, low-fat foods has placed cottage cheese at the center of this trend, making it a valuable product for both established cheese manufacturers and new market entrants.

Meeting the growing demand for cottage cheese production

Even with its rise in popularity, the process of making cottage cheese remains relatively straightforward. It starts with skimmed milk, which is coagulated using lactic acid bacteria and rennet. Then cutted into curds and applied heat during cooking to separate whey from curds. The curds are then drained and washed to remove excess whey and cool them down. The texture and flavor of the curds can be adjusted by adding cream or salt.

However, while the production process itself is simple, scaling it to meet the increasing demand for cottage cheese requires sophisticated machinery and careful attention to quality. The growing demand for cottage cheese means that producers must find ways to produce it efficiently, maintain product quality, and ensure freshness — all while optimizing their production process to meet new consumption trends.

Learn how to make high-quality cottage cheese profitably.

Cottage cheese is the most profitable end product of milk processing. The production of cottage cheese is an almost perfect addition to the product lines of any cheese factory, and MKT Dairy is your partner in learning the process.

MKT Dairy supports the thriving cottage cheese market

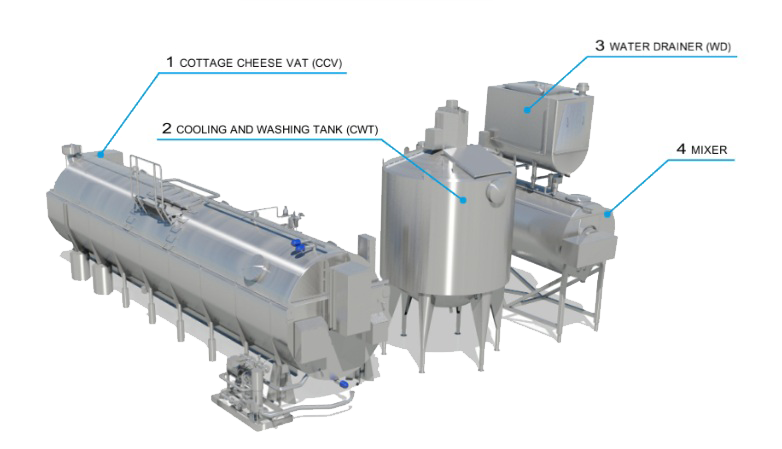

MKT Dairy provides advanced cheese making equipment designed to meet the growing demand in a thriving market. Our machinery optimizes every step of the production process, ensuring product quality, consistency and a high yield.

MKT Dairy’s cutting-edge equipment solutions are crucial for cheese manufacturers looking to stay competitive. By integrating an automated system into the production platform, manufacturers can increase efficiency and reduce both manual labor and the risk of human error.

We provide the technology that allows producers to keep pace with increasing demand while improving their operational efficiency. Whether you’re looking to upgrade existing equipment or optimize your yield, MKT Dairy is committed to providing the tools and support needed for your success in the cottage cheese market.

Contact Us

If you are interested in MKT quality industrial cheesemaking equipment, please get in touch with us to find out more!