The traditional way of making cheese may no longer be able to respond to the needs of modern times. In this blog article, we introduce the strongest trends in the cheese industry.

The range of cheese flavours will increase

Cheese flavours have remained unchanged for a fairly long time. However, we believe that the same thing that happened to products like yogurt will also happen to cheese: their range of flavours will increase significantly. This change is already evident. The pressure is coming increasingly from consumers, because they want – and even demand – new kinds of flavour experiences and constant variety in the cheeses found on their supermarket shelves.

More and more spices, berries and other flavours are being mixed in with cheeses. Here are a few examples of currently popular cheese flavours:

- Hard cheese matured with beer

- Doughnut-shaped breaded camembert

- Semi-hard cheese matured with blueberry

- Edam from fat-free milk with olive oil

- Cottage cheeses with seeds, muesli and grains

- Camel’s milk cheese

- Goat’s cheese with bacon

- Cheddar with bacon

- Camembert with black truffle

- Bacon-wrapped cheese for grilling

- Cheese coated with flowers

- Organic cheeses

- Herb-coated Greek feta

- Feta enriched with probiotics

- Cheeses that can withstand cooking

- Cheese bites with a smoked salmon filling coated with poppy seeds on a stick

- Vegan cheese (lactose and gluten-free)

- Organic emmental coated with pine needles

Experimental batches and variety are becoming increasingly important

As stated above, the range of cheese flavours will grow almost exponentially. Thus, cheese dairies can no longer base their entire production around a single popular product. In the future, cheese dairies must also be able to offer variety – and at a fast pace.

Consumers must be continuously provided with new flavours, the importance of seasonal cheese flavours (such as Christmas specials) will increase, and companies will want to commission unique private label cheeses for their own purposes. Cheese dairies must, therefore, find cost-effective ways of developing their products and making experimental batches.

Technology and automation will revolutionise cheese making

The pressure to increase the range of cheeses and to conduct continuous experimentation and product development set their own challenges for the equipment and technology used in cheese making. This is because large-scale traditional lines, focused on producing only one type of cheese, cannot easily be used to produce single production batches and quick experiments.

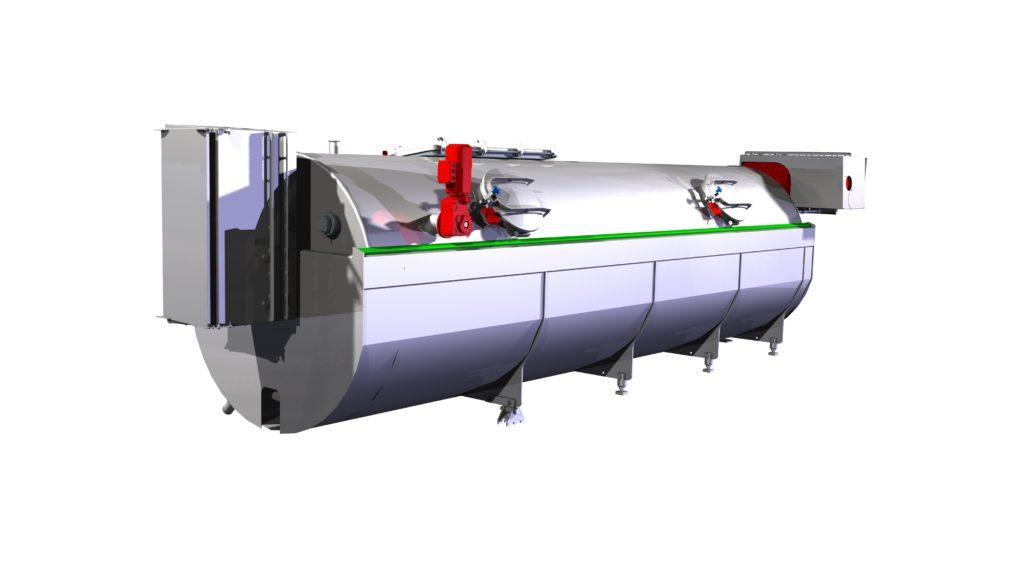

Therefore, modern cheese vats must be flexible and adaptable in a completely new way. After making one batch, the line must be able to produce another completely different one as quickly as possible. Instruments that can be quickly changed and are easy to clean and program can be of tremendous help. With the aid of programmability, several different programs, i.e. recipes, can be stored in the cheese vat’s memory, thus allowing these recipes to be easily adjusted or manufactured without changes with a single push of a button.

Modern cheese vats must be flexible and adaptable. The Multipurpose Cheese Vat in the picture is the answer to the needs of cheese dairies. Click image to enlarge.

Getting rid of excess costs

Flexibility in production helps cheese dairies to react better to their sales. Investment in a new traditional-style production line, based on statistics and assessments, always involves a risk. If the consumers do not discover the new cheese as expected, the investment will result in a massive loss. But if, instead, you have versatile and scalable equipment, you can react to changes in your sales without delay, and any sales that are poorer than anticipated will no longer constitute such a catastrophe for your business.

The increased number of experiments and batches of different types of cheese also means that cheese dairies must put an increased emphasis on product development to ensure that a finished product is always as good as it can be. However, it would not be prudent to sacrifice production batches worth thousands of litres for product development. Instead, a more viable option would be to use MKT’s 50-litre pilot vat for this purpose.

Use our help to take control of trends

Some fairly sizeable trends are visible in the cheese industry, and these will have an inevitable effect on its evolution. We estimate these trends to be such that any cheese dairy looking to succeed should prepare for them.

Our Multipurpose Cheese Vat is the answer to the needs of the modern-day cheese dairy. It will enable the flexible, cost-effective and uniform production of different cheeses. Read more about the Multipurpose Cheese Vat.