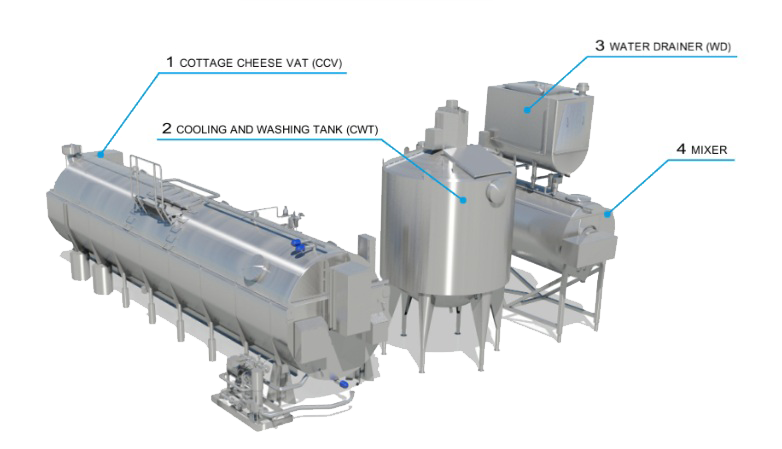

Cottage Cheese Production Lines

OUR COTTAGE CHEESE LINE INCLUDES:

1. Cottage cheese vat

2. Cooling / washing tanks with integrated whey drainer

3. Water drainer

4. Mixer

DOWNLOAD guide to making cottage cheese

Cottage cheese is the most profitable end product of milk processing. The production of cottage cheese is an almost perfect addition to the product lines of any cheese factory.

“We have found MKT’s vats to be superior for the production of cottage cheese, and you get the best value for money.”

-Harri Mikkola, Process Expert, Valio Ltd

A new generation of cottage cheese equipment was brought to the market in 2010, in which the knowledge of the original designers is combined with the newest technology. Equipment’s are made in Finland at our own factory. Factory Acceptance Test is always made so the everything is ready for operation after installation.

Cottage cheese vat, model 2010

MAIN ADVANTAGES

- Customers have compared our vats to competitors and noticed that MKT vats have the best yield

- The first industrial cheese vat on the market with knife cutters instead of wire cutters, for better yield and product safety.

- Mechanically durable due to floating vat design

- Single cut method enables optimal yield and shape of curd cubes

- Lengthwise cutting tool is flushed and comes up from the curd after cutting

- Crosswise cutting tools and stirring tools are on own shafts

- Speed and angle of every moving tool can be adjusted

- Cutting tools can be chosen either with knifes or wires

- CIP -cleaned

- References: 3 vats in Finland, 8 vats in Sweden, 4 vats in Norway, 4 vats in Israel, 1 vat in Estonia, First vat of this new design was delivered to Sweden 2010

Washing/cooling tower with whey separator

MAIN ADVANTAGES

- Whey separator is integrated to washing tower

- Low clean water consumption, about 12 m^3 / 3000 kg cheese curd

- Very good washing and cooling result, washing time about 45-60 min

- Simple and reliable construction and operation

- Designed to be almost service free. No expensive spare parts.

- CIP -cleaned

- References: 7 pcs in Finland, 2 pcs in Norway, 1 pc in Estonia, 1 pc in Denmark

Water drainer

MAIN ADVANTAGES

- Very gentle to the cheese> no pressure force applied to remove the water from grains

- Water separation is based on a vibrating wedge wire screen and a lamella belt

- Very reliable construction

- Designed to be almost maintenance free. No expensive spare parts.

- CIP -cleaned

- References: 5 pcs in Finland, 1 pc in Sweden, 1 pc in Estonia

Creamer

MAIN ADVANTAGES

- Only creamer on the market that can be totally emptied without manual work

- Mixing tools has plastic scrapers which are in contact with inner jacket > this ensures total product output from creamer

- Additional water separation can be done in creamer

- Can also be delivered with tilting function (0°- 3° angle)

- Heavy duty mixer construction with solid shaft

- Water jacket for cooling the product. Product can be stored in the mixer for up to 20 hours.

- CIP -cleaned

- References: 2 pcs in Finland, 4 pcs in Sweden , 6 pcs in Norway, 1 pc in Estonia,1 pc in Denmark

Many projects in production at our factory

Due to the increased consumption of cottage cheese the demand of new machines and production lines are strong.

THE VARIOUS BENEFITS OF COTTAGE CHEESE PRODUCTION

1. Excellent profit. Cottage cheese is currently one of the most profitable end products in milk processing. Due to the volume of the production, the profitability of semi and hard cheese is currently low, but the profit for cottage cheese production is good. Factors that influence the better profitability of cottage cheese include the favorable competitive situation for special cheeses and better opportunities for the modification and branding of the products.

2. A fast and straightforward production process. Unlike the lengthy production and maturing processes of basic cheeses, the production process of cottage cheese is short, and the cheese is packed straight for the consumers without maturing. The production of cottage cheese is fast, and the production process easier to manage.

3. The production line won’t take much space. A cottage cheese production line can often be placed within the existing premises of the cheese factory. This makes a cottage cheese production line a good expansion option for existing cheese factories.

INTERESTED IN COTTAGE CHEESE PRODUCTION?

We are happy to help cheese factories start cottage cheese production and succeed in it. Here are a few reasons to choose MKT Cottage Cheese Line:

Turn-key delivery. We supply the entire cottage cheese production line, including cottage cheese vat, cooling/washing tank, integrated whey drainer, and cottage cheese creamer. We also supply quality packing machines through our network. This allows you to get all equipment effortlessly from one place.

High yield percentage. The yield of our fully automatized and efficiently washing cottage cheese production line is top of the market. Our equipment allows the efficient utilization of available milk, which enables good profitability.

Reliable quality. Our cottage cheese equipment is used by the largest dairies producing cottage cheese all over Europe.

MKT Cottage Cheese Vat – Full of Great Features

MKT Cottage Cheese Vat is controlled with Siemens PLC, and frequency converters are used to adjust the speeds of all tools. It is mechanically durable due to floating vat design and solid shaft materials.

Customers have compared our cheese vats to our competitors’ and noticed that MKT cheese vats have the best yield. Main advantages of using MKT Cottage Cheese Vat are:

- Single cut method enables optimal yield and shape of curd cubes.

- Lengthwise cutting tool is not inside the product after cutting but automatically lifted up.

- Short distance from the tools to the tank wall (10 mm) ensures there is less remaining uncut curd and the mix is optimal.

Our cheese vat has automatic rennet distribution: when rennet is poured to rennet distribution tank, tank pressurizes automatically and rennet is sprayed evenly to the milk inside the cheese vat.

Heating unit is also integrated: there are a steam adjustment valve, a heat exchanger and pump for a vat-heating water circuit. PLC controls steam flow and optimizes temperatures of heating water for different heating stages. The system is CIP–cleaned with 8 pieces of Alfa Laval Sanimagnum sprayballs.

Learn how to make high-quality cottage cheese profitably.

Cottage cheese is the most profitable end product of milk processing. The production of cottage cheese is an almost perfect addition to the product lines of any cheese factory, and MKT Dairy is your partner in learning the process.

TECH SHEETS

MKT CCV – England

MKT CCV – Spain

MKT CCV – Japan

MKT CCV – Bulgaria

MKT CCV – Czech

MKT CCV – Hungary

MKT CCV – Brazil

MKT CCV – Russia

MKT CCV – Israel

MKT CCV – Arabic

MKT CCV – China

MKT CCV – Greece

MKT CCV – Turkey

MKT CCV – Portugal

MKT CCV – Latvia

MKT CCV – Netherlands

MKT CCV – Norway

MKT CCV – Poland

MKT CCV – Estonia

MKT CCV – France

MKT CCV – Italy

MKT CCV – Lithuania

MKT CCV – Denmark

MKT CCV – Deutschland